Custom Kiosk Design

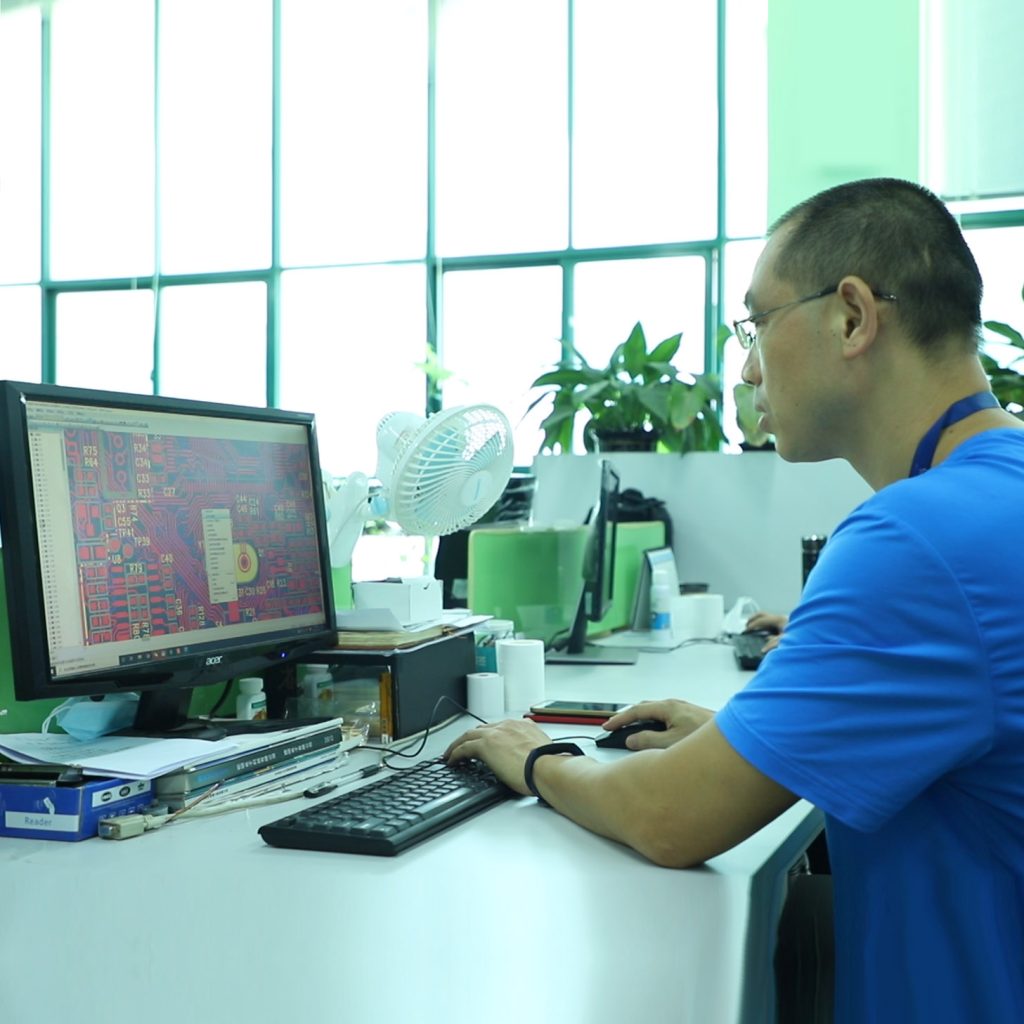

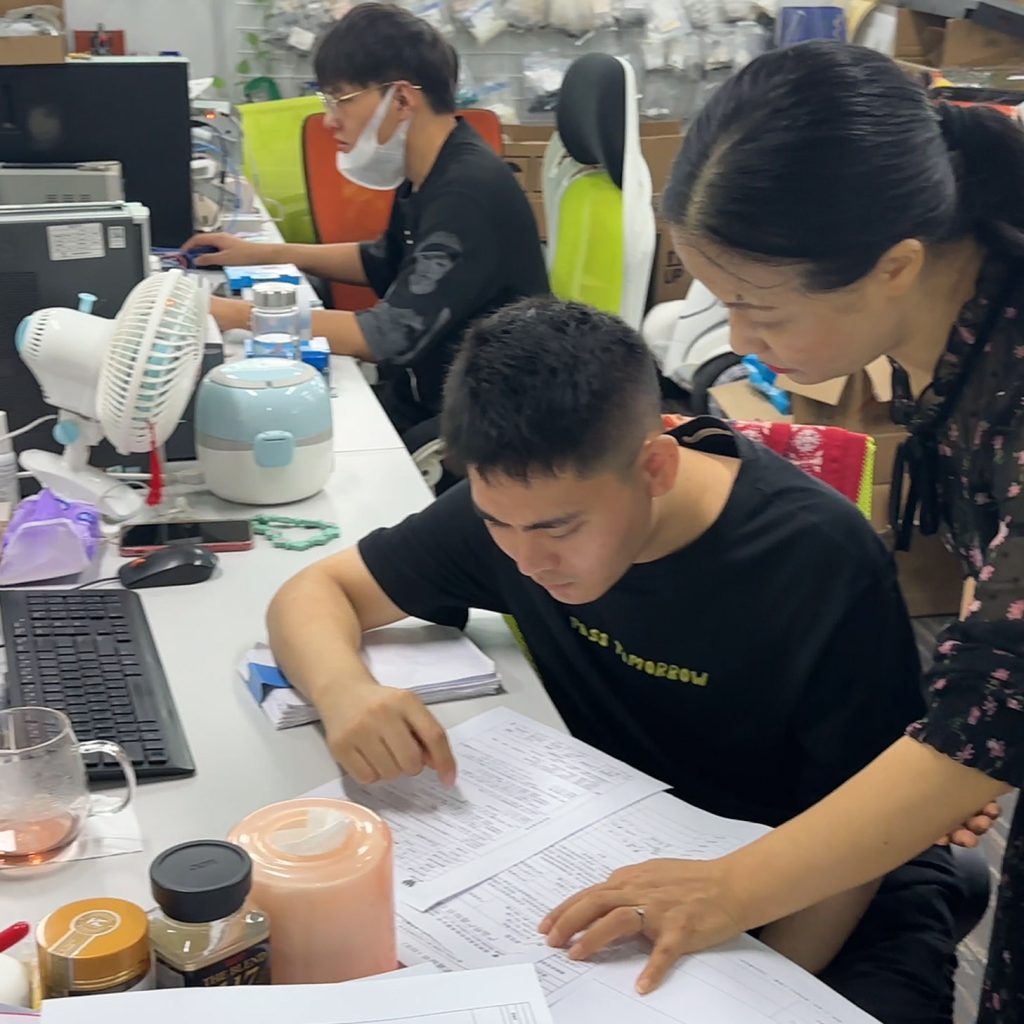

Design Experience

For 19 years, we have accumulated extensive experience in over 17 vertical markets, proving our R&D capabilities and providing an unparalleled foundation of experience in self-service terminal customization.

Choosing Masung for self-service terminal design offers unique advantages in two aspects:

Solution Teams Include:

While most clients have general kiosk design ideas and preferences, there is no need to know how to design a kiosk. Masung professionals will consult with you on how to build your own kiosk elements into a design that meets your aesthetic and functional needs. Further, we can recommend components and features that help you meet the intended custom kiosk functionality and price range for hardware and related support services. In short, we’ll make it easy for your company to hit your custom mark.

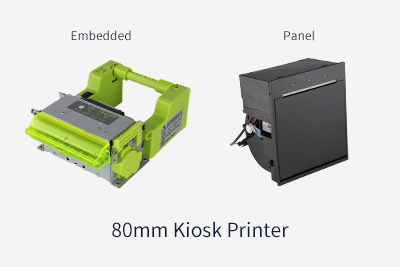

Custom Component

Integration

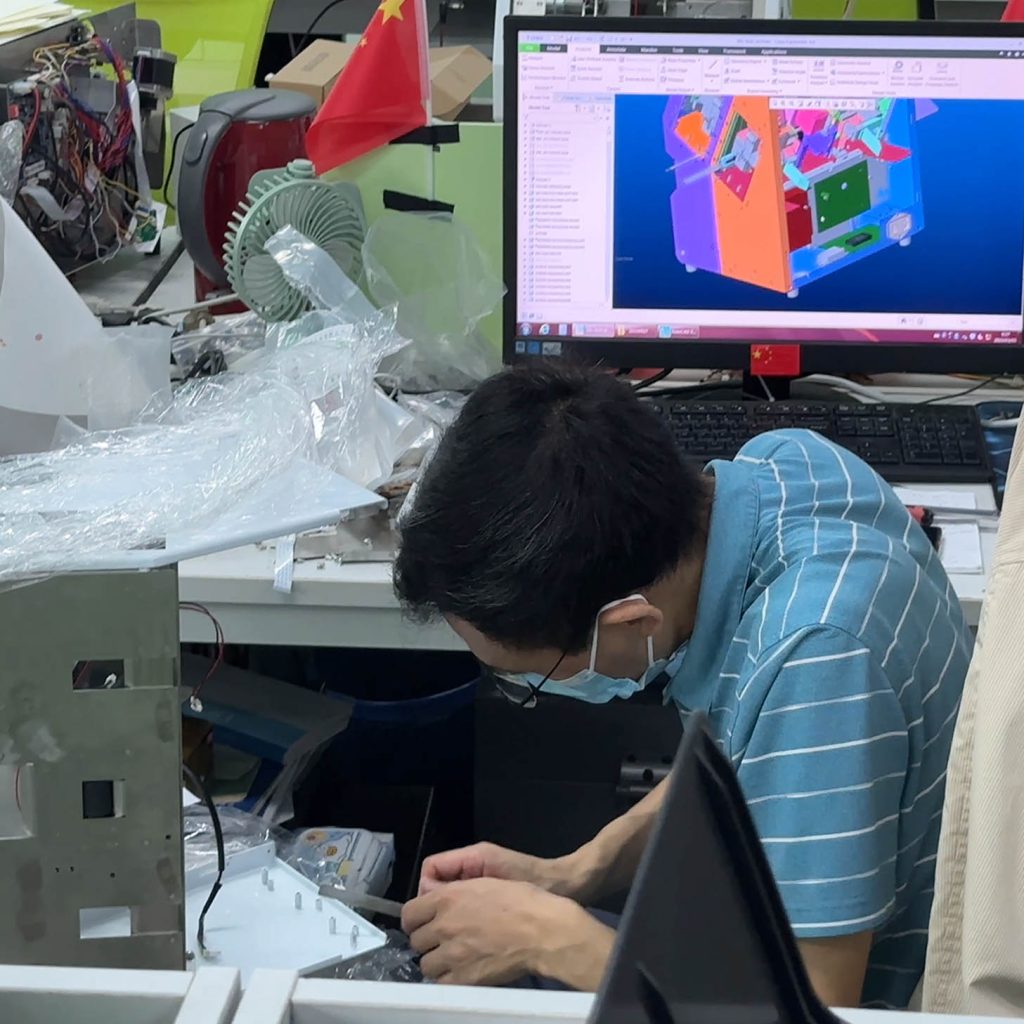

Masung can accommodate component-heavy transaction requirements

As a manufacturer of multifunctional financial services, airport security screening, and rental platform solutions, we frequently integrate 15 to 20+ distinct peripheral devices. More commonly, Masung serves clients requiring “light customization” creative designs—economically integrating a small number of unique accessories or components into standard self-service terminals.

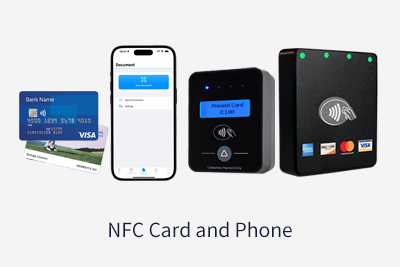

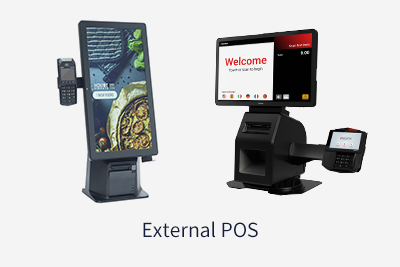

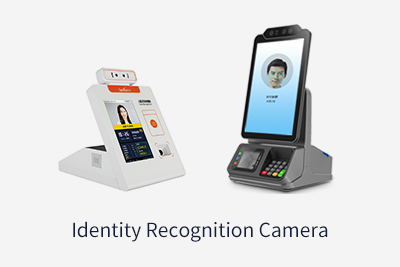

Integration Capabilities Include:

This is simply a sampling of custom component integrations. If you don’t see it listed, just ask – most anything is possible.

Custom Kiosk Gallery

Self-service kiosk solutions for major global enterprises. If you require a similar self-service kiosk solution, please contact us.

More Custom Solutions

Simply tell us the application scenarios for your self-service kiosk, and leveraging our project experience, we can provide you with a professional customized solution covering everything from sheet metal design to hardware configuration and functional requirements.

First, based on the engineering workflow documents from the self-service terminal (Masung), we consult with the client to establish comprehensive design standards. This includes budget, schedule, component requirements, installation, and scalability. The final design requirements document is continuously refined throughout the project, addressing all design issues early on based on extensive past experience.

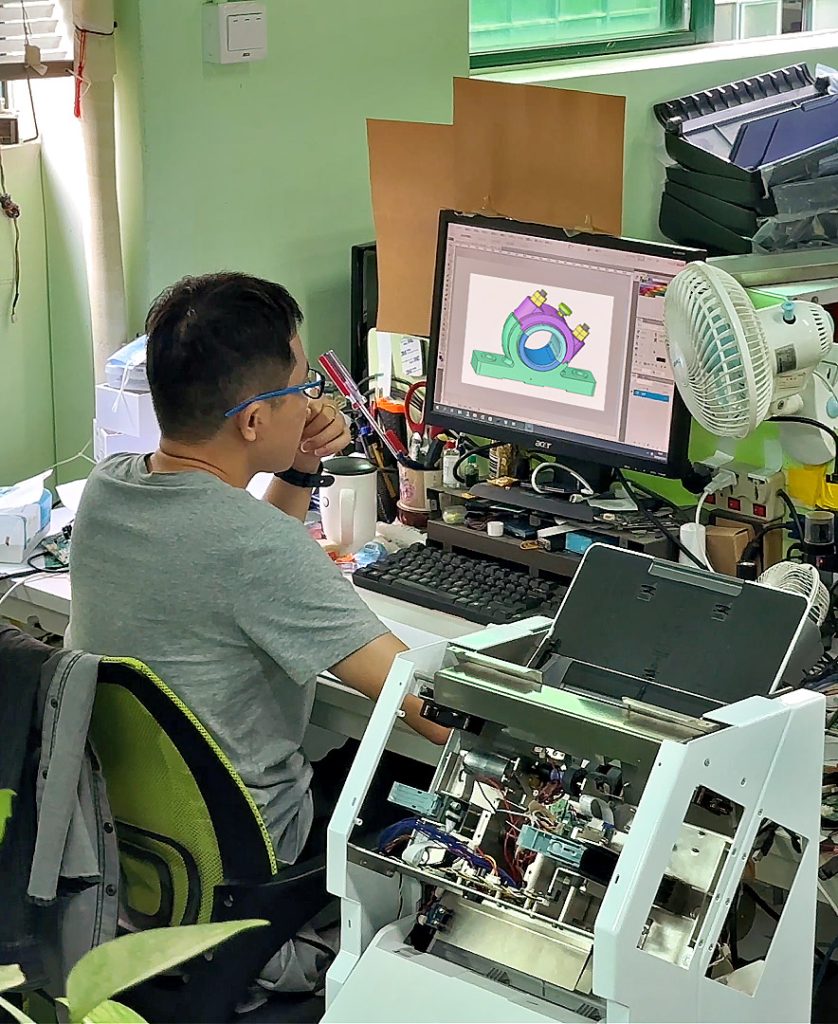

Complete the full set of mechanical drawings. Conduct design reviews to ensure all requirements are met and generate a list of necessary changes. Finalize the design based on client feedback, ensuring compliance with relevant specifications.

Components are procured based on the confirmed design requirements document, ensuring compatibility with the customer’s specific software. The customer must review and approve the component specifications before initial layout modeling of the overall casing begins at the self-service terminal.

The prototype components undergo “dry fit” testing inside the chassis. After passing the tests, painting, pattern design, and final assembly are completed for first-piece production. Masung’s specialized engineers are responsible for UL and FCC testing of each internal component to accelerate time-to-market and oversee all stages of prototype development.

Once a component is approved, we will create initial concept diagrams to validate the component layout and achieve the desired aesthetic effect. This iterative process requires close collaboration between Masung’s engineering team and the client’s project team, providing multiple creative solutions that balance manufacturability and reliability.

After the prototype was delivered, we utilized its 40,000 square meters of manufacturing space for in-house manufacturing and production, meeting a wide range of production needs from small to large batches. Masung provided comprehensive on-site and managed services to ensure seamless deployment and professional support at all production scales.